Hydraulic presses for BANF insoles fixing

The distinctive feature of the technologies produced by Elettrotecnica B.C. team it is the high adaptability; in fact, along sixty years of activity, we have come in contact with many different realities within the footwear production field, whose needs are encouraging us to always find a more innovative, more functional, more effective system than the previous one.

This feature is reflected in our BANF hydraulic presses for insoles fixing: the production rate is higher than any other on the market, thanks to the approach speed of the pistons. In addition, in some models we bring an even greater innovation: we have in fact developed a technology for inserting the insole exactly in the desired position inside the mold and to keep it locked during the pressing phase.

Do you want to find all about the technical features of our BANF hydraulic presses for insoles fixing? Browse the catalog!

Contact us!

Go to the form to ask about our products!

Models

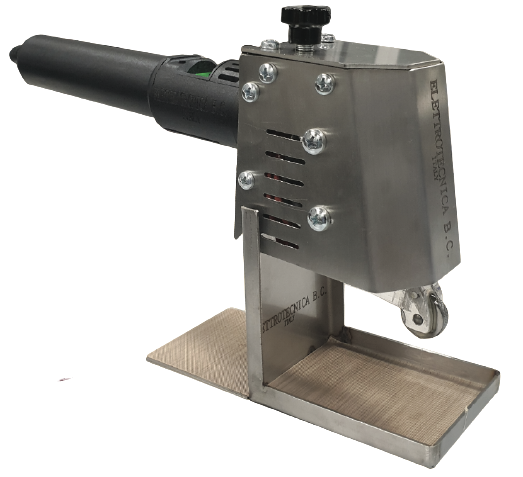

Hydraulic press for insoles

Machine very noisless, it permits a production higher than any other in trade, for its approach speed of the pistons.

The dimensions of the pistons, with large diameter, permit high power in tons, without high-pressure working, therefore with a greater safety of employment.

Its hydraulics system, easy and practical, is the better warranty of elimination of any trouble and obstacle.

| Technical details | |

|---|---|

| Dimensions: | Cm 90 x 67 x 165 |

| Net weight: | Kg 620 |

| Absorbed power: | Kw 1,5 |

| Obtenible power: | T 32 |

| Planes port: | mm 230 |

Hydraulic press for insoles and soles

Machine very noisless, it permits a production higher than any other in trade, for its approach speed of the pistons.

The dimensions of the pistons, with large diameter, permit high power in tons, without high-pressure working, therefore with a greater safety of employment.

Its hydraulics system, easy and practical, is the better warranty of elimination of any trouble and obstacle.

| Technical details | |

|---|---|

| Dimensions: | cm 120 (47”) x 90 (35”) x 165 (65”) |

| Peso limpio: | Kg 690 (1520 LBS) |

| Absorbed power: | Kw 2.0 |

| Obtenible power: | T 32 |

| Planes port: | mm 230 (9”) |

| Planes dimension: | mm 230 (9”) X 480 (19”) |

Hydraulic press for insoles and soles

Machine very noisless, it permits a production higher than any other in trade, for its approach speed of the pistons.

The dimensions of the pistons, with large diameter, permit high power in tons, without high-pressure working, therefore with a greater safety of employment.

Its hydraulics system, easy and practical, is the better warranty of elimination of any trouble and obstacle.

| Technical details | |

|---|---|

| Dimensions: | cm 120 (47”) x 90 (35”) x 165 (65”) |

| Net weight: | Kg 690 |

| Absorbed power: | Kw 2,0 |

| Obtenible power: | T 32 |

| Planes dimension: | mm 230 (9”) X 480 (19”) |

| Planes port: | mm 230 (9”) |

Insole moulding press with manually leading and automatic unleading

With this machine we have optained something that till now has never been realized: the insole pressing inserted in the stamp in the wanteed position, in order to avoid eventual movings during the pressing operation.

This is possible using the belt conveyer which allows:

- to put the insole on the belt against some indicated points allowing so the repetition of the series.

- to have the pressing with the insole always stopped in the wanteed position during the same, as, mean while the stamp goes down and begins to press on the insole, the insole it is stopped in the original position through a tightened belt till that there is contact with the counterstamp.

Of course, in conseguence of the belt conveyer, during the pressing the operator of the machine must put on the belt another insole in the right position of centering, as when the timer of the pressure time open the stamps, automatically there is the pressed insole discharge and the charge of the new to be pressed.

The machine has two oleodynamic autocompensating cylinders on which there are the counterstamps in order to allow the use of couple of stamps which are already used on other machines; as with our press is possible to use each type of stamp even if produced by other firms.

The used belt allow to warrentee a medium validity from 1 to 3 months each, this depending from the done work and particularly to the counterstamp preparation which have not to have corners or cutting edges which can damage the belt.

The output can vary from 600 to 900 pairs each hour:

1 - adjusting the pressing timer from 1 to 6 seconds;

2 - raising or reducing the feeding speed.

The oleodynamic and pneumatic parts are closed in sure panels and are always ready for an easy checking.

The electric plant positioned in the front of the machines has been studied in order to give more guarantee for the during and functionality time, as the electric power of the electrovalve and of the contacts is of 24 Volts each.

In the plant there is insereted a safety system with a photoelectric cell barrier which protect the operator against eventual incidents in the case that he puts the hands or something other in the same during the pressing operation.

| Technical details | |

|---|---|

| Dimensions: | Cm 200 (79”) x 100 (39”) x 185 (73”) |

| Net weight: | Kg 1800 ( 3968 LBS) |

| Absorbed power: | Kw 5,5 + 0,5 |

| Power: | Tonn. 68 |

Insoles moulding press with manually leading, automatic unleading, insoles separation group and radiator cooling for oil

With this machine we have optained something that till now has never been realized: the insole pressing inserted in the stamp in the wanteed position, in order to avoid eventual movings during the pressing operation.

This is possible using the belt conveyer which allows:

1 - to put the insole on the belt against some indicated points allowing so the repetition of the series.

2 - to have the pressing with the insole always stopped in the wanteed position during the same, as, mean while the stamp goes down and begins to press on the insole, the insole it is stopped in the original position through a tightened belt till that there is contact with the counterstamp.

Of course, in conseguence of the belt conveyer, during the pressing the operator of the machine must put on the belt another insole in the right position of centering, as when the timer of the pressure time open the stamps, automatically there is the pressed insole

discharge and the charge of the new to be pressed. The machine has two oleodynamic autocompensating cylinders on which there are the counterstamps in order to allow the use of couple of stamps which are already used on other machines; as with our press is possible to use each type of stamp even if produced by other firms.

The used belt allow to warrentee a medium validity from 1 to 3 months each, this depending from the done work and particularly to the counterstamp preparation which have not to have corners or cutting edges which can damage the belt.

The output can vary from 600 to 900 pairs each hour:

1 - adjusting the pressing timer from 1 to 6 seconds;

2 - raising or reducing the feeding speed.

The oleodynamic and pneumatic parts are closed in sure panels and are always ready for an easy checking.

The electric plant positioned in the front of the machines has been studied in order to give more guarantee for the during and functionality time, as the electric power of the electrovalve and of the contacts is of 24 Volts each. In the plant there is insereted a safety system with a photoelectric cell barrier which protect the operator against eventual incidents in

the case that he puts the hands or something other in the same during the pressing operation.

| Technical details | |

|---|---|

| Dimensions: | cm 200 (79”) x 100 (39”) x 185 (73”) |

| Net weight: | Kg 1800 |

| Absorbed power: | Kw 5,5 + 0,5 |

| Power: | Tonn. 68 |

Insoles moulding press with manually leading, automatic unleading, with conveyor and collecting insoles

With this machine we have optained something that till now has never been realized: the insole pressing inserted in the stamp in the wanteed position, in order to avoid eventual movings during the pressing operation.

This is possible using the belt conveyer which allows:

1 - to put the insole on the belt against some indicated points allowing so the repetition of the series.

2 - to have the pressing with the insole always stopped in the wanteed position during the same, as, mean while the stamp goes down and begins to press on the insole, the insole it is stopped in the original position through a tightened belt till that there is contact with the counterstamp.

Of course, in conseguence of the belt conveyer, during the pressing the operator of the machine must put on the belt another insole in the right position of centering, as when the timer of the pressure time open the stamps, automatically there is the pressed insole

discharge and the charge of the new to be pressed.

The machine has two oleodynamic autocompensating cylinders on which there are the counterstamps in order to allow the use of couple of stamps which are already used on other machines; as with our press is possible to use each type of stamp even if produced by other firms.

The used belt allow to warrentee a medium validity from 1 to 3 months each, this depending from the done work and particularly to the counterstamp preparation which have not to have corners or cutting edges which can damage the belt.

The output can vary from 600 to 900 pairs each hour:

1 - adjusting the pressing timer from 1 to 6 seconds;

2 - raising or reducing the feeding speed.

The oleodynamic and pneumatic parts are closed in sure panels and are always ready for an easy checking.

The electric plant positioned in the front of the machines has been studied in order to give more guarantee for the during and functionality time, as the electric power of the electrovalve and of the contacts is of 24 Volts each.

In the plant there is insereted a safety system with a photoelectric cell barrier which protect the operator against eventual incidents in the case that he puts the hands or something other in the same during the pressing operation.

| Technical details | |

|---|---|

| Dimensions: | Cm 116 (43”) x 167 (65”) x 200 (78”) |

| Net weight: | Kg 1800 |

| Absorbed power: | Kw 5,5 + 0,5 |

| Power: | Tonn. 68 |

Insoles mouldin press with manually leading, automatic unleading conveyor and collecting insoles, insoles separating group and radiator cooling for oil

With this machine we have optained something that till now has never been realized: the insole pressing inserted in the stamp in the wanteed position, in order to avoid eventual movings during the pressing operation.

This is possible using the belt conveyer which allows:

1 - to put the insole on the belt against some indicated points allowing so the repetition of the series.

2 - to have the pressing with the insole always stopped in the wanteed position during the same, as, mean while the stamp goes down and begins to press on the insole, the insole it is stopped in the original position through a tightened belt till that there

is contact with the counterstamp.

Of course, in conseguence of the belt conveyer, during the pressing the operator of the machine must put on the belt another insole

in the right position of centering, as when the timer of the pressure time open the stamps, automatically there is the pressed insole

discharge and the charge of the new to be pressed.

The machine has two oleodynamic autocompensating cylinders on which there are the counterstamps in order to allow the use

of couple of stamps which are already used on other machines; as with our press is possible to use each type of stamp even if

produced by other firms.

The used belt allow to warrentee a medium validity from 1 to 3 months each, this depending from the done work and particularly

to the counterstamp preparation which have not to have corners or cutting edges which can damage the belt.

The output can vary from 600 to 900 pairs each hour:

1 - adjusting the pressing timer from 1 to 6 seconds;

2 - raising or reducing the feeding speed.

The oleodynamic and pneumatic parts are closed in sure panels and are always ready for an easy checking.

The electric plant positioned in the front of the machines has been studied in order to give more guarantee for the during and functionality time, as the electric power of the electrovalve and of the contacts is of 24 Volts each.

In the plant there is insereted a safety system with a photoelectric cell barrier which protect the operator against eventual incidents in the case that he puts the hands or something other in the same during the pressing operation.

| Technical details | |

|---|---|

| Dimensions: | Cm 200 (79”) x 100 (39”) x 185 (73”) |

| Net weight: | Kg 1800 ( 3968 LBS) |

| Absorbed power: | Kw 5,5 + 0,5 |

| Power: | Tonn. 68 |

PHOTO GALLERY

Contact us for more informations!

Fill out this form to request informations about our products.