Heel seat pounding machines

A fast and efficient production cycle with a reduced number of issues is one of the elements that characterizes a serious and professional footwear manufacturer, making it perceived by the customers as the best choice on the market.

At Elettrotecnica B.C. we have been working alongside producers of excellence all over the world for sixty years: our technologies follow and ease the production steps of the shoe manufacturers who choose us..

One of the most requested and most appreciated machines is the heel seat pounding machine: the different models we provide can adapt to the needs of each shoe manufacturer, reaching a perfect leveling of the seat where the heel is going to be applied. Rotation speed and adjustable translation, soundproofing system and heated plate are just some of the features that make our heel seat pounding machines the best on the market.

Find out all the technical details, browse the catalog!

Contact us!

Go to the form to ask about our products!

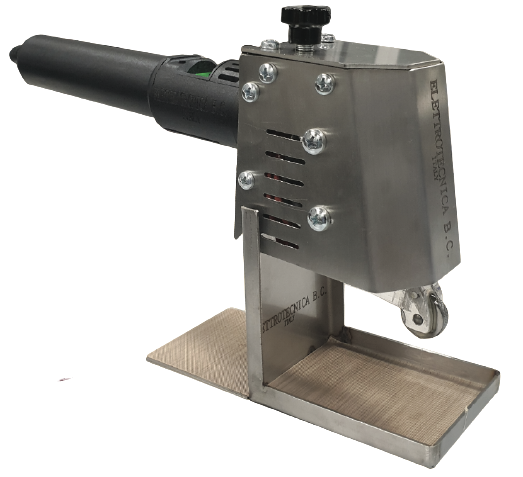

Heel seat pounding machine with vibrant hammer and hot plate

- Hell seat pounding machine with vibrating hammer ideal for tilting the heel seat.

- Equipped with Soundproofing System.

- Adjustable rotation speed and travel.

- Piastra riscaldata per una migliore spianatura della boetta.

- Heated plate for better plating of the boetta.

- Machine cycle managed by PLC.

| Technical details | |

|---|---|

| Dimensions: | cm 65 (26”) x 85 (33”) x 159 (63”) |

| Net weight: | Kg 370 (816 LBS) |

| Electric Power: | Kw 0,5 |

| 6 bar air consumption: | 15 lt/cycle |

| Hourly production: | 1000 / 1500 |