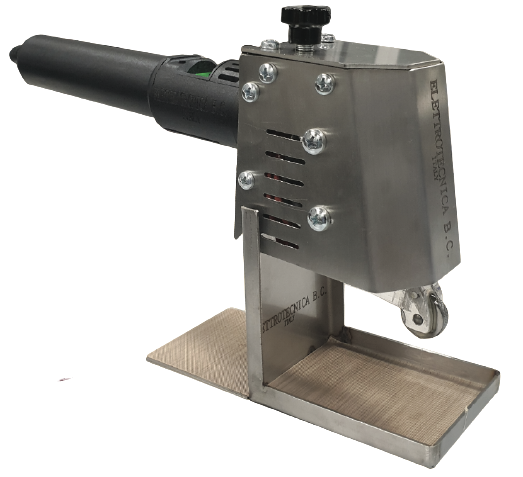

Cold stabilizers

The deep understanding of all the potential belonging to a production process is not often a simple task; above all, it is not easy to understand how much broader this same potential could be with the use of a certain type of technology.

The Elettrotecnica B.C. team offers 360° counseling to help its customers choose the most suitable machinery to support and increase their production capacity. Furthermore, our technologies are always the most innovative on the market: our cold stabilizers, for example, have the best defrost and insulation system, with Power Save utility that enables a 30% electricity saving.

Furthermore, the perfect bonding is guaranteed by the action speed, which allows to speed the footwear stabilization times and the polymerization times of the water-based glues.

Find out all the features of our cold stabilizers and the available models!

Contact us!

Go to the form to ask about our products!

Conveyor belt cold conditioning unit

The programmed conditioning unit permits rapid cooling, of all the footwear previously Heat-treated, resolving problems deriving from rapid work cycles

- it accelerates stabilisation Times of the footwear and the polymerisation times of the water based cements, guaranteeing perfect Sealing

- - it rapidly cools and stabilises soles and shoes produced by the p.u.

- machines rink system compatible, - a touch screen colors permits to simplifying use for the Operator

- the new system is equipped With work cycles, in which is possible configure the machine to have load and unload from the Same part

- optimization extra ventilation programmed cycle, to get the maximum cold stabilization.

- the program is fitted with a function to calculate automaticly the permanent time of The footwear in base of the material type and the productivity that you want.

| Technical details | |

|---|---|

| Daily production: | 600 pairs in 8 hours |

| Dimensions: | cm. 99(39,5”) x 106(41”) x 148(58”) |

| Net weight: | Kg 362 ( 798 LBS) |