Glue thermal reactivation machines

One can see when the product quality is at a high level: our mission is our commitment to helping our customers reach a higher and higher standard as well as an increasingly efficient fluency in working processes.

Our thermal reactivation machine models are conceived and designed with exactly this purpose: to provide absolute precision and less effort in the manufacturing process. Infrared lamps are used to quickly heat the sole and the shoe glued parts: the technology is designed to ensure that the sole does not soften too much, especially if built in materials such as PVC.

There are also some technical features that make our thermal reactivation machines even more efficient, such as the self-adapting shoe support system and sole. Working comfort and precision are further guaranteed thanks to a series of parameters that can be conveniently adjusted according to your needs, such as the lamps lighting time or the inclination of the sole carriage.

Find out all the models of thermo reactivation machines in our catalog!

Contact us!

Go to the form to ask about our products!

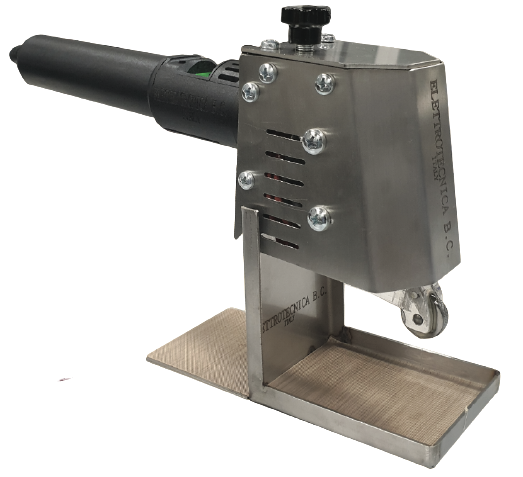

Reactivating machine for solvent base cement and water base cement

- Cement reactivating machine, by means of special quartz heating elements, enabling rapid reheating

of the cement-coated part of the sole and shoe - Independent temperature regulation for sole and shoe.

- Auto-levelling support system for sole and/or shoe.

| Technical details | |

|---|---|

| Dimensions: | cm. 80 (32”) x 80 (32”) x 160 (63”) |

| Net weight: | Kg 95 (209 LBS) |

| Gross weight with crate: | Kg. 140 (308 LBS) |

| Gross weight with case: | Kg. 165 (363 LBS) |