Moisturizing machines

How is it possible to understand if a technology might be more suitable for a certain type of business? You must rely on experts in the field, like a company that is able to understand the special features and the critical points of a manufacturing process and knows how to recommend the perfect solution to speed up the workflow, while at the same time increasing the finished product quality.

For over sixty years, our team has been committed to assisting and supporting customers in analyzing and understanding which technology is the most appropriate: for this reason, we offer different types of moisturizing machines. In our catalog, you can find sprayers equipped with photocells for the automatic start of the softener quantity, as well as machines with sprayers provided with two or more positions and more.

Each machine has specific characteristics to meet the needs of the manufacturer with innovative and functional solutions, such as the production of steam in a small boiler that avoids the formation of stains on the upper, considerably reducing both water consumption and limestone formation.

Would you like to know more about our technologies to moisturizing the upper? Browse our catalog!

Contact us!

Go to the form to ask about our products!

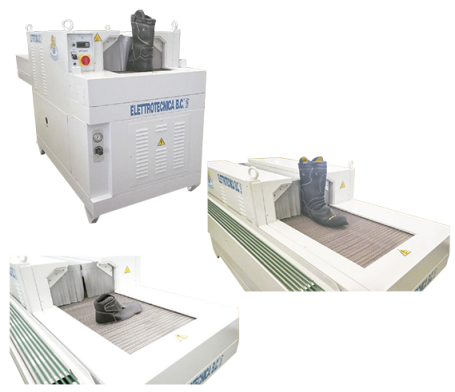

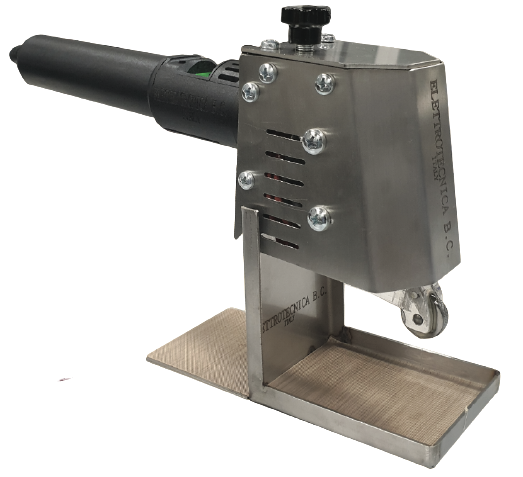

Electro-pneumatic machine programmed to humidify toe and side also reactivate the toe before lasting. - patented -

The upper is in direct contact with the heated pad, humidifying the toe and side areas in a few seconds.

An important feature of this machine is the fact that the steam is instantly produced in a small boiler,

hence avoiding possible spots on the shoe upper and significantly reducing water consumption and limestone problems.

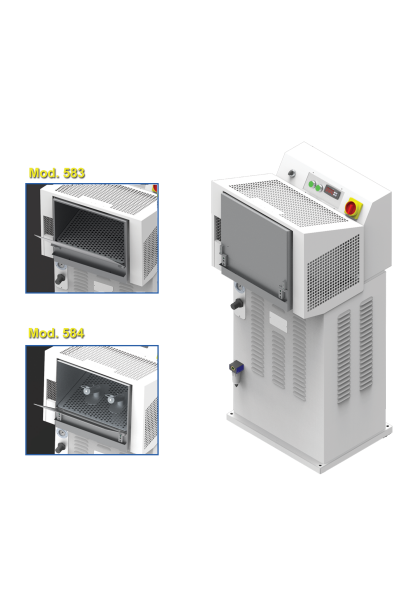

Featuring a new steam injection system from the lining side. Auto-programmed colour display.

- The toe lasting programme can be synchronised with the humidifier programme.

- Steam injection on the upper side and the tip lining side.

- The steam on the leather side and the upper lining side can be excluded.

- 30% energy saving.

- All materials are auto-programmed.

| Technical details | |

|---|---|

| Air consumption at 6 Bar: | 7 Lt/Min |

| Dimensions: | cm. 36 (14”) x 59 (23”) x 132 (52”) |

| Net weight: | Kg. 57 {126 LBS) |

| Electric power: | 1,7 kW |