Stabilizing furnaces

Shoes manufacturers know well: when you want to offer a top quality product, every little detail can make the difference.

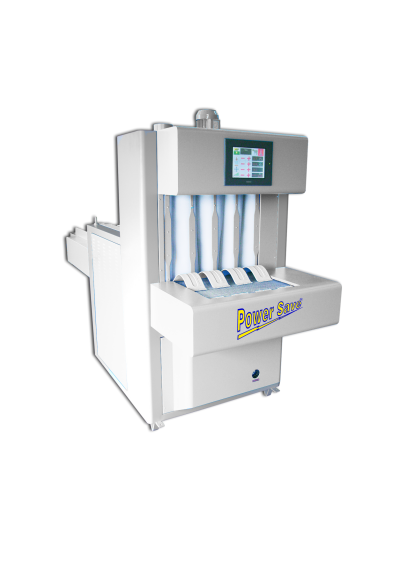

For this reason, our machines are designed to guarantee attention in every single step of a shoe production. Our stabilizing furnaces are able to stabilize and eliminate shoe imperfections with the highest precision; and yet it's not just this feature making them so unique. In fact, they have an air recycling system, together with the Power Save circuit that allow you to save up to 30% of electricity.

The Elettrotecnica B.C. branded stabilizing furnaces are designed to support different production quantities per hour, depending on the manufacturer's needs; among other features, it is also allowed to settle the transport speed and the steam production.

Find out the stabilizing furnaces technical details in our catalog!

Contact us!

Go to the form to ask about our products!

High performance heat setter with autosetting thermal treatment, with final temperature reducer and inspiration hood - patent pending -

Machine to stabilize with hot steamed air all kind of footwear on last. System of automatic calculation rifle steam and temperature in relation of the output production. Visualization given of production and time of permanence of the footwear. Visualization percentage of humidity. Program preset up to you for the different material with possibility to set the heat treatment to article. Movement conveyor automatic depending to the request temperature. Fast reduction of the temperature in excess. System touch-screen video colours. System searches breakdowns automatic with resolution of the problem. System of heat reduce on shoe to the exit of the thermal treatment.

- Times of the adjustable thermal treatments until 25”

- Temperature of the treatments adjustable until 200°C (392°F)

- Percentage of adjustable humidity until to one production of 3500cm3/h of steam

- heat climate room, conveyor belt and steamer are in stainless steel material.

| Technical details | |

|---|---|

| Dimensions: | cm 105(41”)x 310(122“)x 192(75,5”) |

| Net weight: | Kg 550 (1212 LBS) |

| Electric power: | 20,9 Kw |