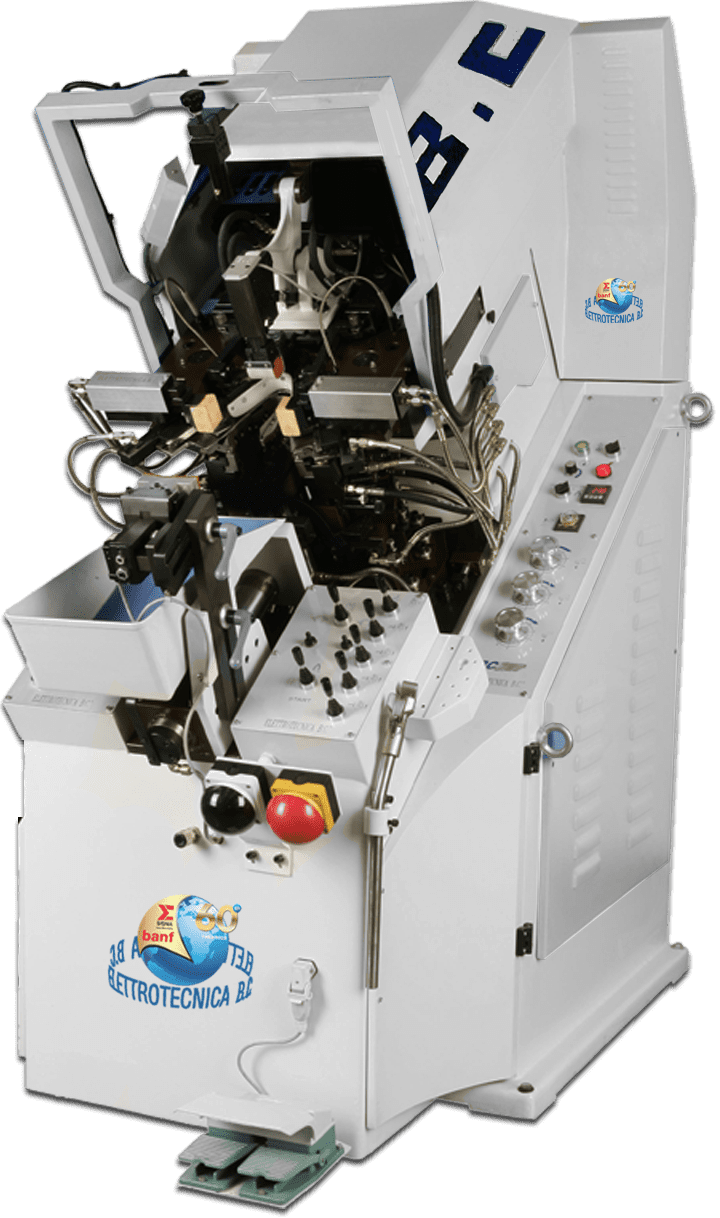

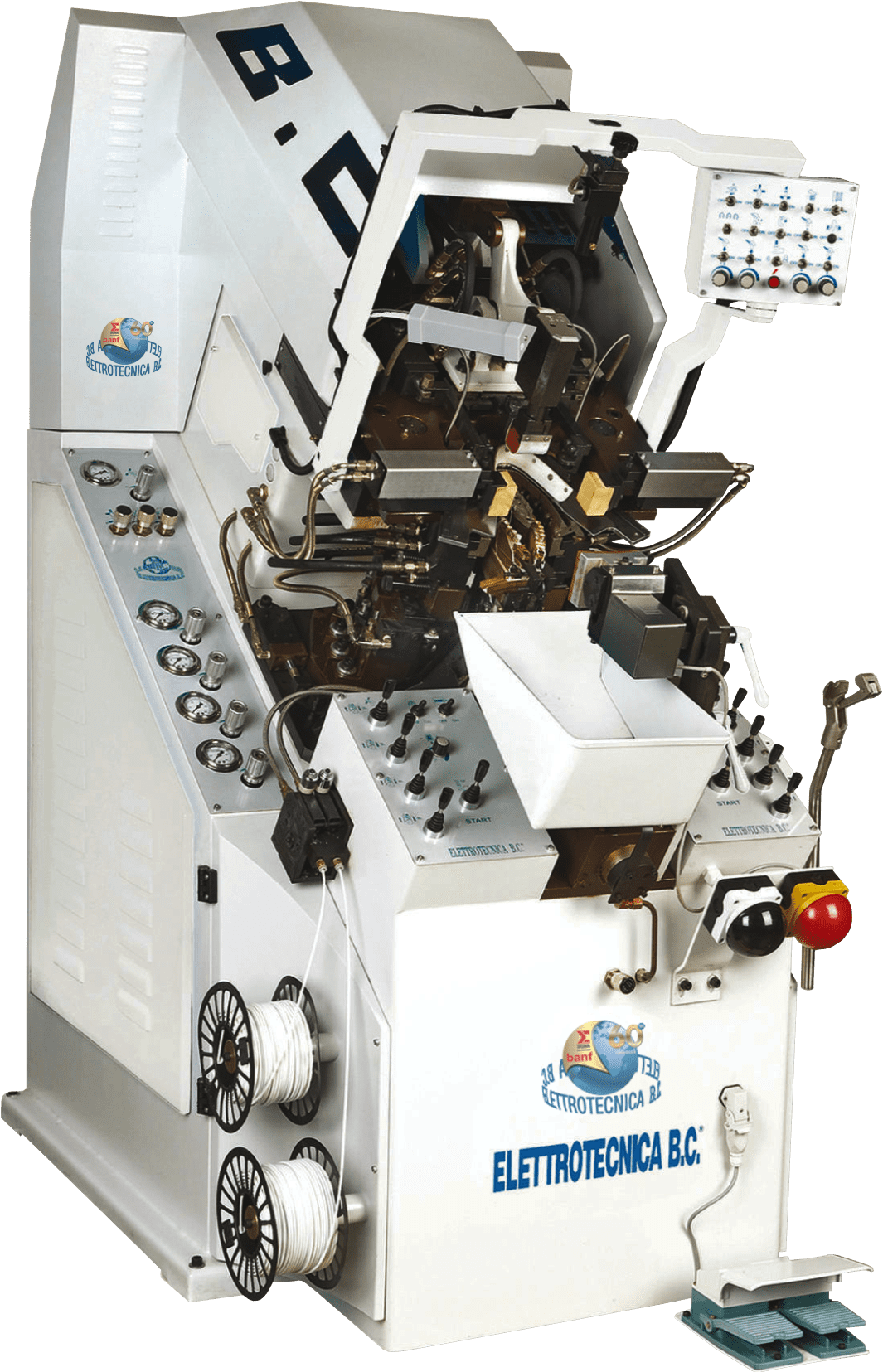

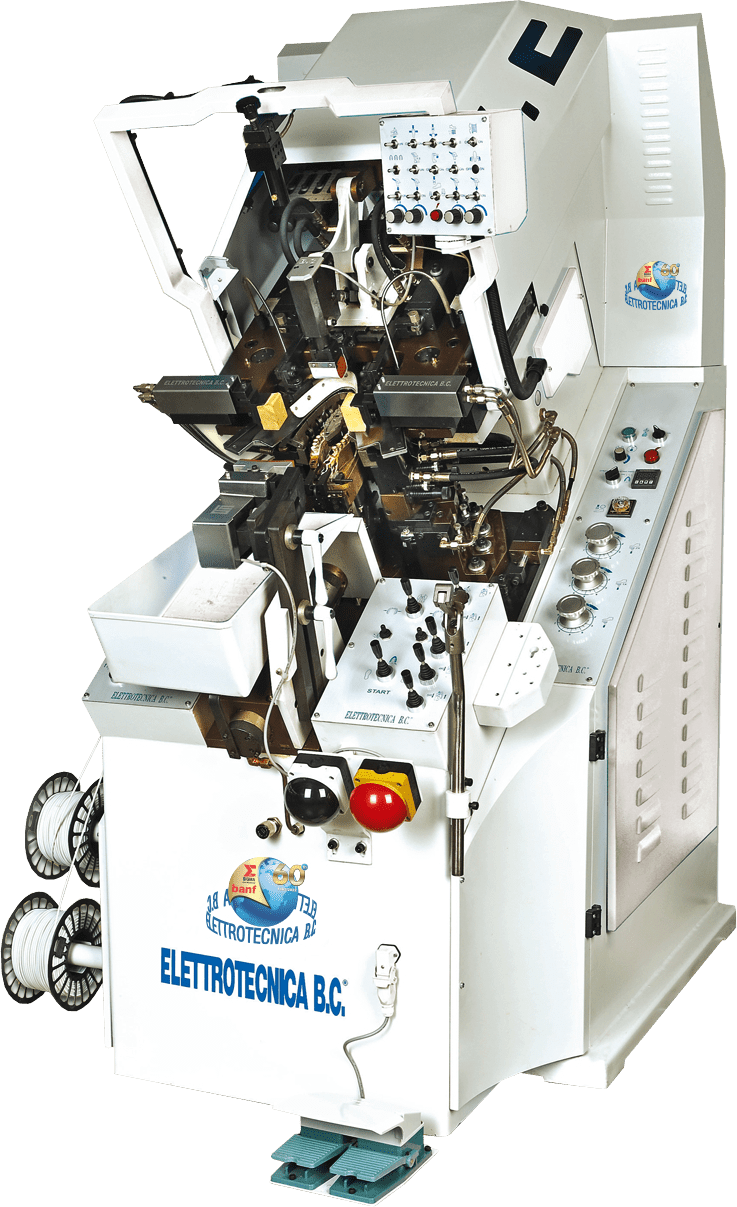

Pulling over lasting machines

One of our designed technologies regards our pre-assembly/lasting machines , we have toe lasting machines models for shoes for all styles of footwear, lasting machines for children's shoes, lasting machines for women's shoes, lasting machines for men's shoes, lasting machines sneakers, safety shoes lasting machine, lasting machines goodyears, lasting machines ideal and other preassembly/lasting machines for all assembly needs; how can we facilitate the phase in which the front part of the shoe is assembled, which can differ so much between one model and another? And here is our answer: Elettrotecnica B.C. is equipped with an intuitive self-adjustment system that allows you to produce any type of footwear in the shortest time and with guaranteed simplicity.

A complete range of adjustable parameters and highly performing technical features complete the precision and functionality of these lasting machines.

"In sixty years of activity, we at Elettrotecnica B.C. have always put a special focus on footwear manufacturers and their needs: for this reason, every day we strive to find solutions to problems and needs that a precision work requires, which must always be perfect in every slightest detail".

Find out all the details and models of the pre-assembly/lasting machines on our catalog!

Pulling over and toe lasting machine full optional with ti, with tracers

- System LPD (Last Position Detect)

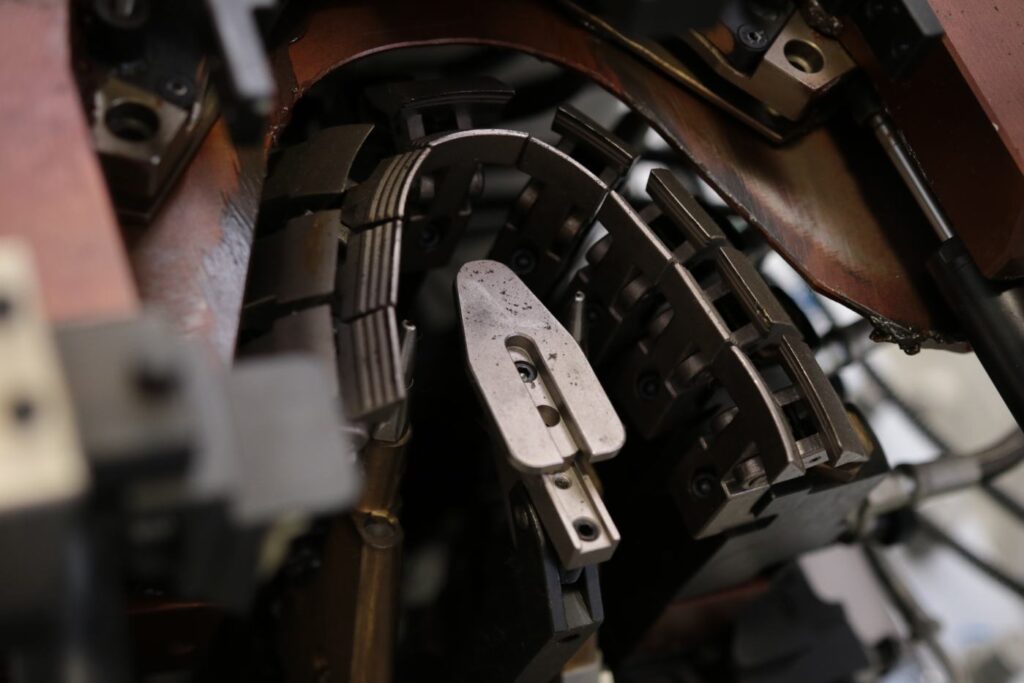

- 9 pincers with revolving pincer 5

- Cementing system with programmed tracers

- Tracer movement with brushless motors for have highest precision at high speed

- Cement profile set is in scale 1:1 with digital display

- Colour display with 100 expandables programs

- Model codes personalized

- Programmed head movement

- Programmed wipers movement

- Last support double release (with mechanical detention for stop precision)

- Setting position of pincers with 5 axial system adjustable separately between the left and right pincers group

- Setting position of pincers with horizontal opening for a quickly use of the different lasts models

- Independent side bands and teflon band

- Optical projector

- Last support adjustment with external handles

- Pressing pressure, teflon band, side bands, spoon wipers, climb applicator, low pressure pincers,

pincers closing, all external adjustable with reading manometer - Tool box included

- Setting connection with mod. 140,241S, 182, 230, 241. The mod. 700 RCP as as more, the programmable back band and digital reading of last support quota.

| Technical details | |

|---|---|

| Daily Production: | 250 pairs/hour |

| Electric Power: | 3 Kw |

| Working pressure: | 5 Mpa |

| Dimensions: | cm. 114(45") x183(72")x210 (83") |

| Net weight: | Kg 1100 |

| Gross weight with cage: | Kg 1300 |

Contact us!

Go to the form to ask about our products!