Spurs shaping machines

Each step of the shoe production process must be carried out in a careful and precise way, to avoid that a simple detail can compromise the final quality result.

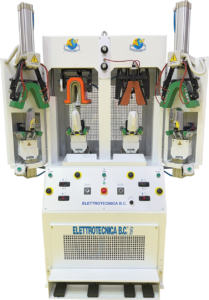

This is why Elettrotecnica B.C. has designed different types of spurs shaping machines: each of them has specific features that are well suited to different types of production and activities, while ensuring unique reliability and safety to support manufacturing.

Our machines are conceived to give the desired shape to the back of the shoe and can be equipped either with hot stations, cold stations or even hot stations with steam. Being well adaptable to any situation, these technologies can be chosen accurately according to the features they present, such as the electronic control system with digital display of the mold temperatures or the sharp and facilitated view of the upper rear part during the loading phase. Furthermore, the molds are built on the outline of the customer's desired shape.

Find out all technical details of our spurs shaping machines, browse our catalogue!

Contact us!

Go to the form to ask about our products!

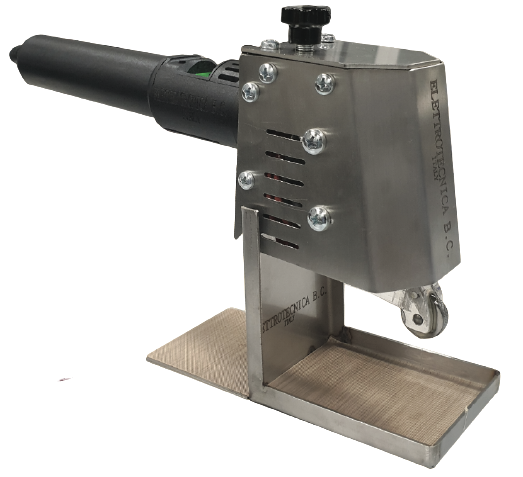

Forepart activating and toe pre-shaping machine

- The machine is particulary indicated to process uppers with thermoplastic or thermoadesive coated toe-puffs.

- Clear view and precision during loading of the upper onto cooled mould, thanks to movable mechanical stops with graduated scale.

- Electronic control with digital visualisation of heated and cooled moulds temperatures.

- Possibility of adjustment/adapting to different upper thickness from lighter uppers to the more thick ones.

- The heated moulds are constructed according to the shape of costumer’s last.

| Technical details | |

|---|---|

| Dimensions: | Cm 153 x 85 x 171 |

| Net Weight: | Kg 418 |

| Absorbed Power: | Kw 1,8 |