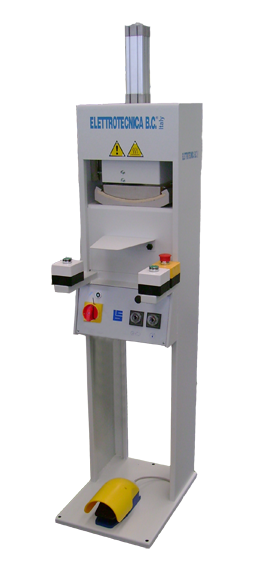

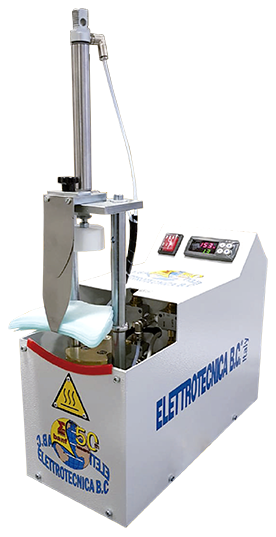

Tip fixing machines

Elettrotecnica B.C. vocation, for sixty years, has been to design technologies that can help shoe manufacturers to produce quality items, free from defects, to make their customers' experience fully satisfying.

This vocation continues to inspire us even today: from our experience come our tip fixing machines, with one or two places.

Our models, designed for applying the pre-glued reinforcement toecap, are equipped with a device which is locking the toecap onto the upper before pressing: this system is highly appreciated as it prevents the toecap from moving and any defects or problems in processing.

Both the buffer temperature (up to 250 °) and the pressing time (up to 30 seconds) are adjustable.

Browse our catalog and find the more suitable model for your needs!

Contact us!

Go to the form to ask about our products!

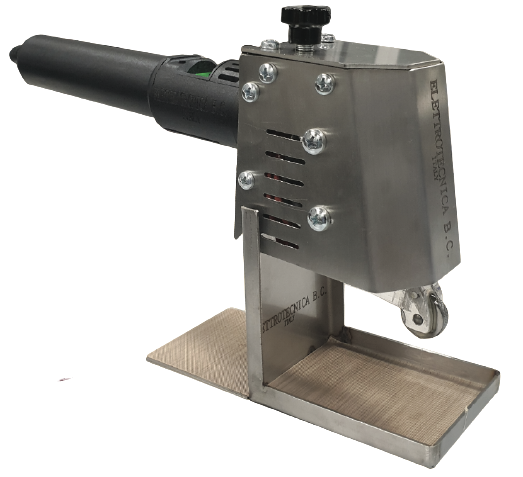

Automatic tip loader with tip preheating

During the production process, the machine facilitates and reduces the operating time.

Thanks to preheating, it is possible to place in an easier way the tip on the upper compared to the traditional systems, obtaining a

higher quality product while increasing productivity.

| Technical details | |

|---|---|

| Dimensions: | cm 16 (6,3”) x 40 (15,7”) x 50 (19,7”) |

| Net weight: | Kg 19 (42 LBS) |

| Electric power: | Kw 0,15 |

| Hourly production: | 300 pairs |