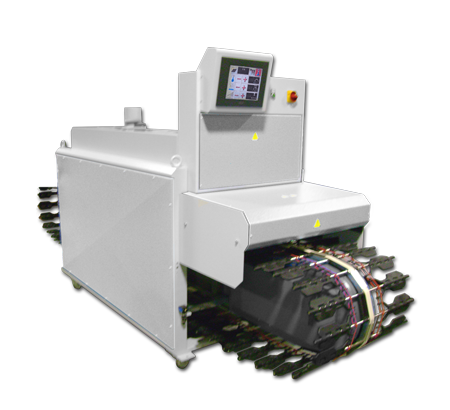

Reactivators dryers

Our sixty years experience in the field of footwear production machines has allowed and continues to let us always be one step ahead of the manufacturers' requirements. In this way, we can foresee and find a solution for any need arising during the work processes.

For this reason, our catalog includes different types of reactivating dryers: what makes them special, among other top quality technical features, is the patented shoe / sole transport system, which allows the machine to fit independently from the type of shoe.

Furthermore, the different models can maintain different working frequency, according to the requirements; the time needed to complete the glue drying and reactivation process on the sole and shoe is ten times shorter than traditional machines.

Another feature that makes the Elettrotecnica B.C. branded reactivating dryers unmistakable, are the different options, such as the opportunity of adjusting both the transport speed and the temperature for soles and shoes, as well as the inclusion of a safety system which, in the event that some problem arises during the processing, prevents the overheating of soles and footwear.

Find out the different models in our catalog!

Contact us!

Go to the form to ask about our products!

Cement drying machine

The cemented surfaces are dried and reactived in 2-3 minutes as apposed to 25-30 minutes, in the past. In addition to substantial time saving this also reduces the number of last required. The specially designed conveyor enables soles and shoe/boots to travel in pairs thus easing assembly work by the operator. Moreover, the conveyor is adapted to any type of sole or shoe/boot.

Rink system compatible.

- Reactivation is effected by special quartz heating elements.

- Independent temperature control is provided for soles and shoe/boot

- Transport speed can e adjusted according to output requirements

- An appropriate dain pipe discharges waste solvents

- Should processing problems arise, precision safety systems will prevent overheating of soles and shoes.

| Technical details | |

|---|---|

| Dimensions: | cm 102 (40”) x 965 (380”)x 172 (68”) |

| Net weight: | Kg 950 ( 2095 LBS) |

| Daily production: | 600 / 2500 pairs |