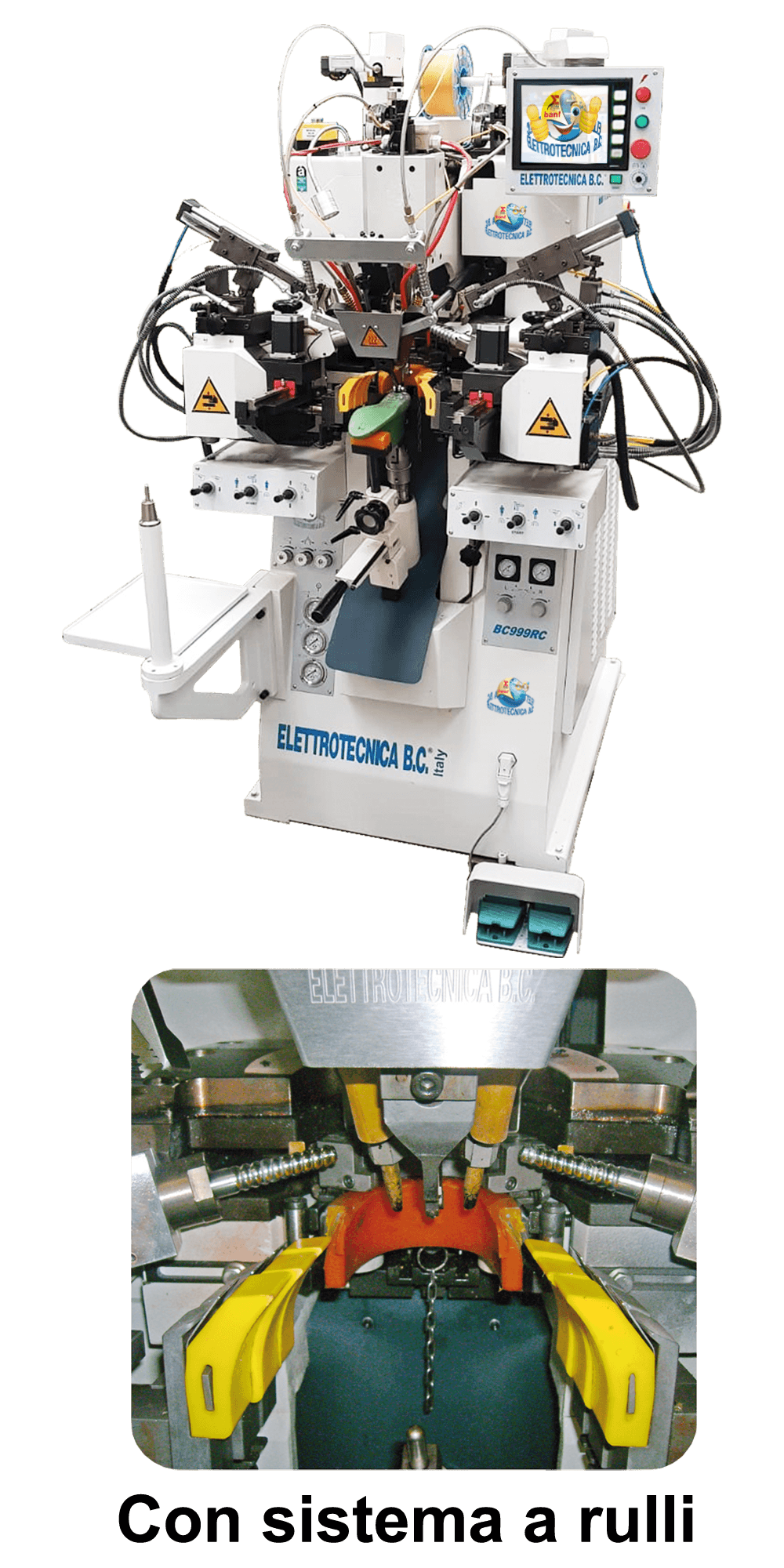

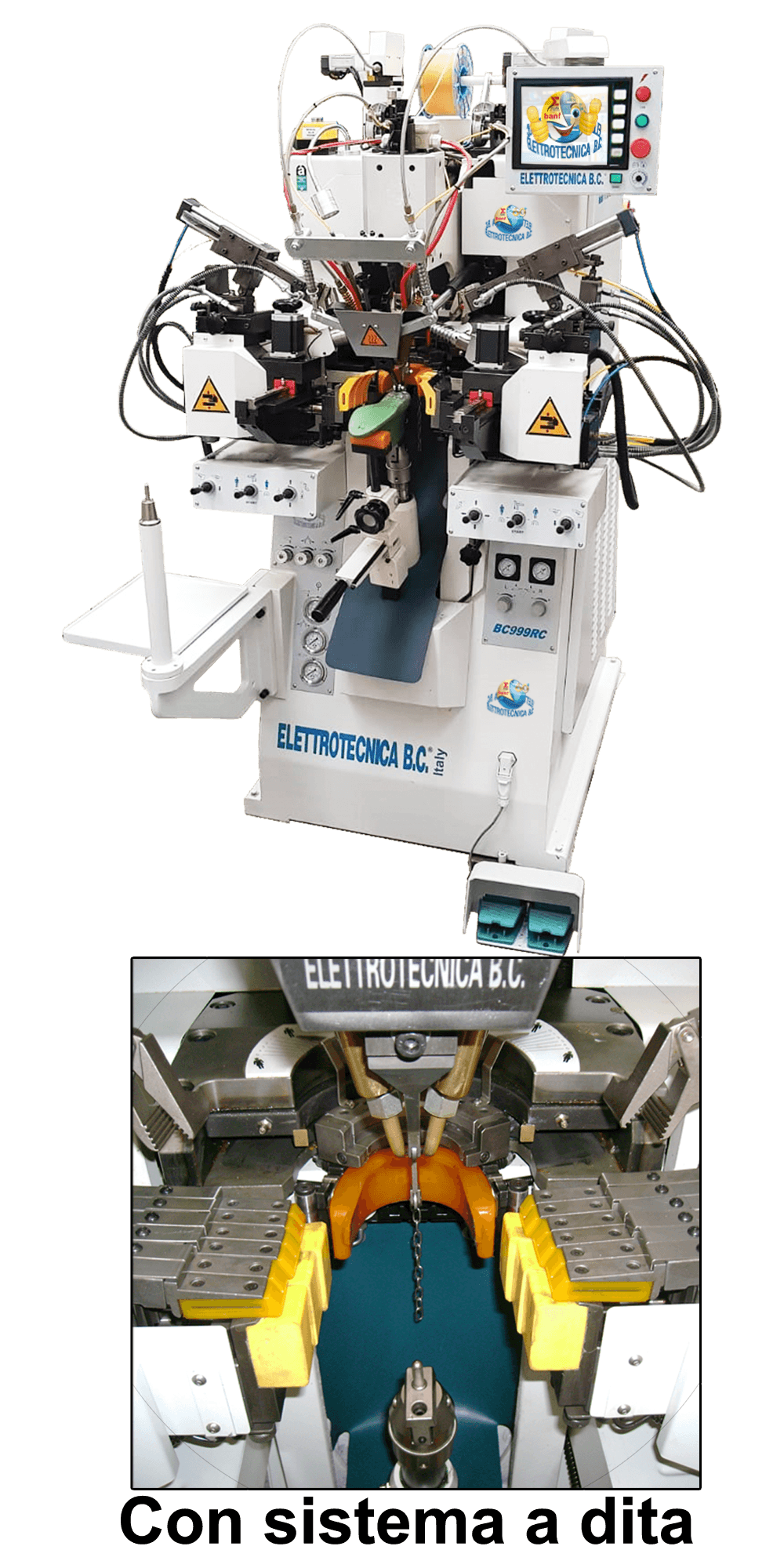

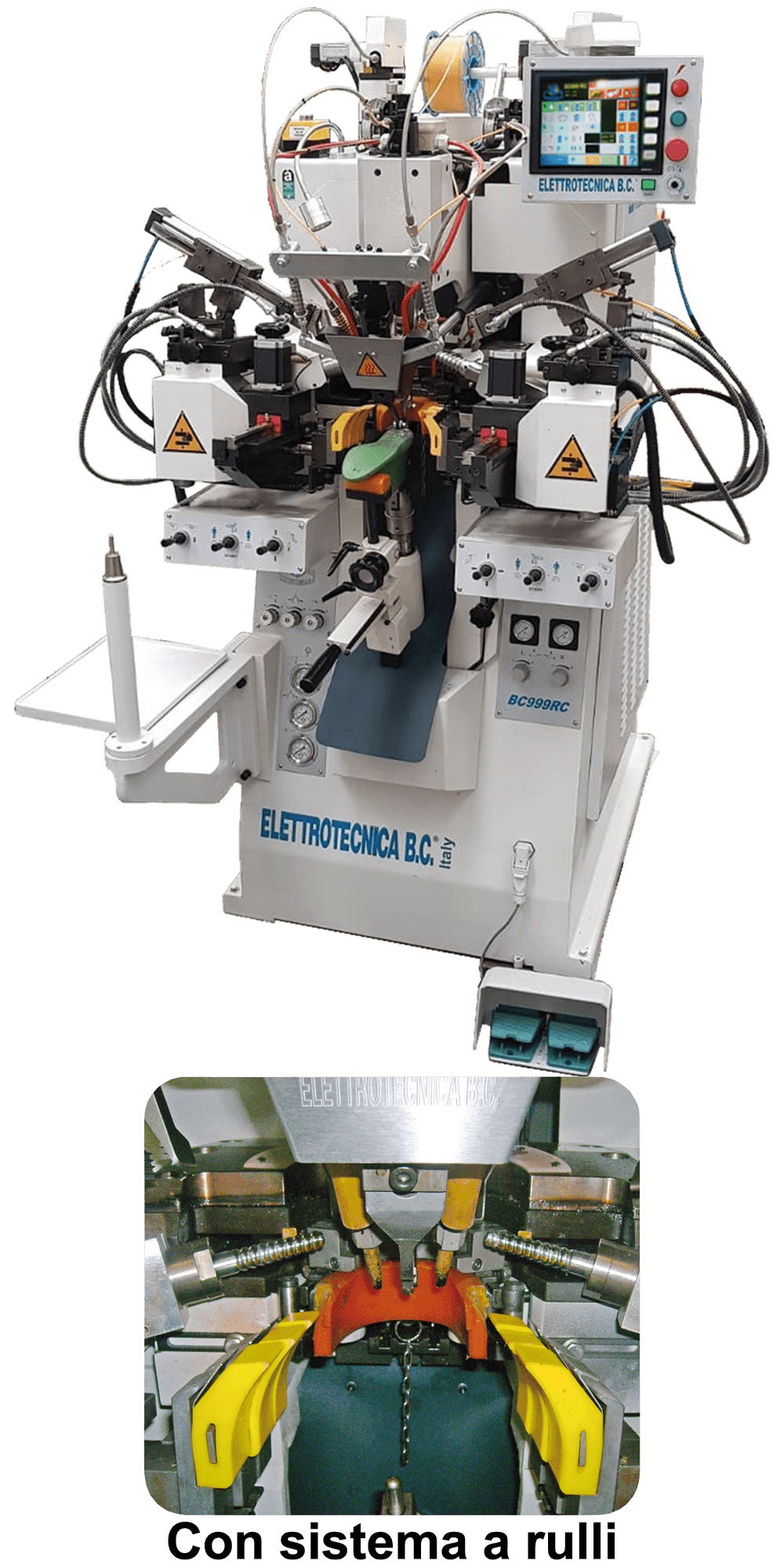

Heel seat lasting machines

If they asked to the Research and Development team, which every day deals with making the technologies designed by Elettrotecnica B.C. even more efficient and innovative, what most distinguishes their heel seat lasting machines, what answer would they give?

With no doubt, the flexibility! The assembly process of the shoe rear part is completed quickly and with the highest precision, thanks to the opportunity of adjusting many parameters on which the outcome of this production step is depending. But that's not all: our heel seat lasting machines are able to go from processing one shoe model to another in less than thirty seconds! This is a key factor for shoe factories, which can so gain larger and larger market share.

Find out our heel seat lasting machine models and their technical features to find out which one best suits your needs!

Contact us!

Go to the form to ask about our products!

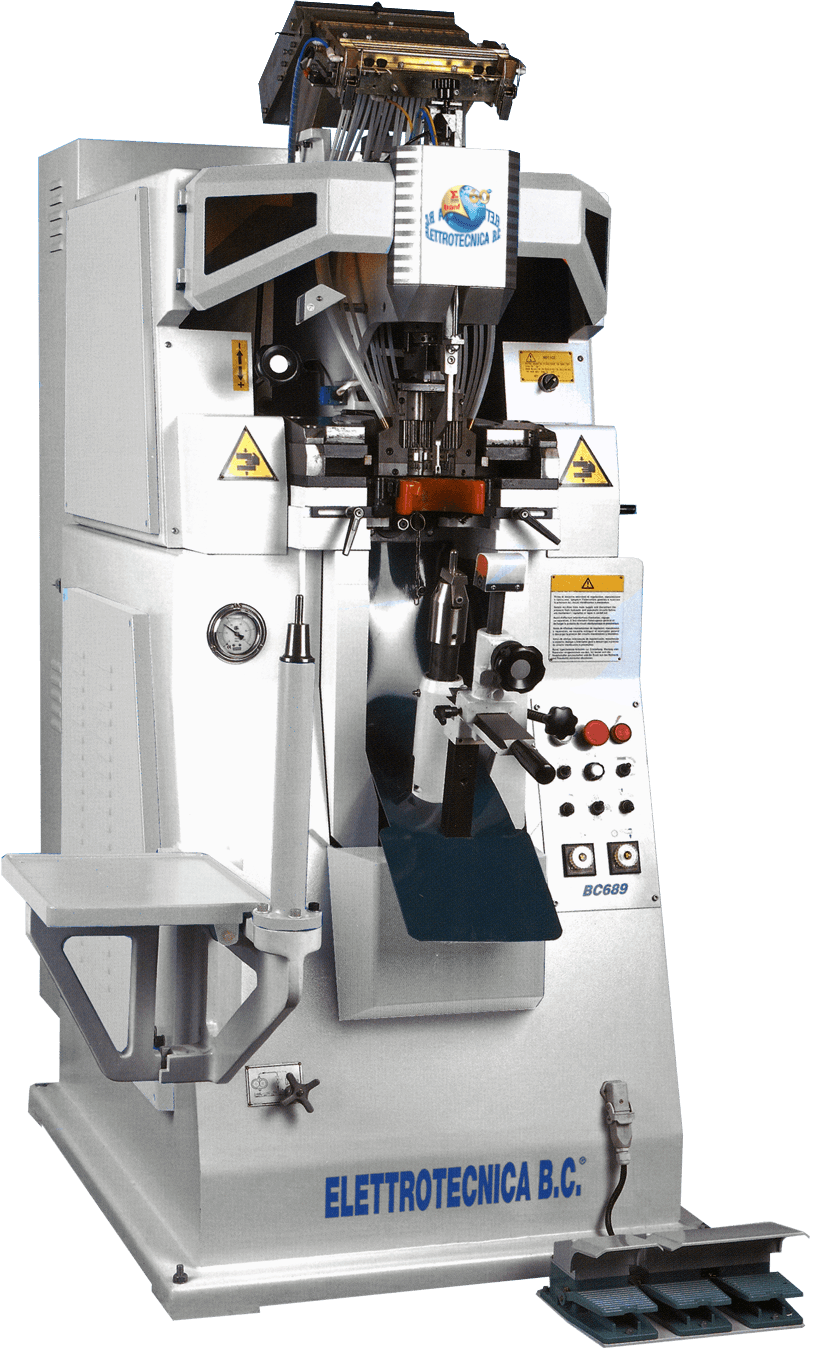

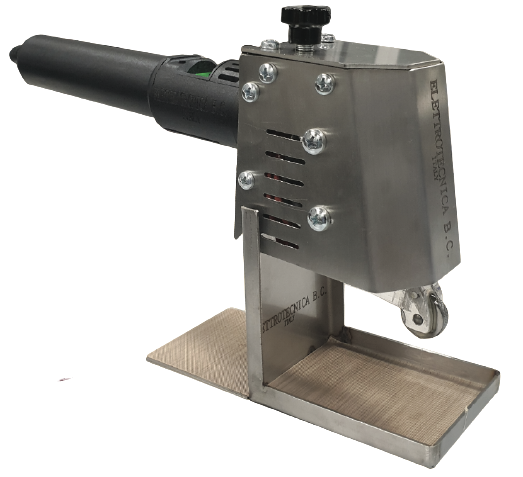

Side lasting machine

Lastin machine with hot melt rod adhesive application.

The machine is complete with a range of all the components necessary for adaptation for different work operations:

- Tapered roller speed variator.

- Glue and tapered rollers pedal control (aut/man).

- Pounding roller temperature control.

- Pounding roller angle adjustment.

- Pounding roller pressure adjustment.

- Adhesive quantity precision control.

- Continuous adhesive supply with pedal control.

- Electronic adhesive temperature adjustment.

- Easy removable glue melter.

The various adjustment control system make this machine ideal for all types of materials and shoe models/lasting.

| Technical details | |

|---|---|

| Dimensions: | cm 62 (24”) x 80 (31”) x 175 (69”) |

| Net weight: | Kg 220 (485 LBS) |

| Electric power: | Kw 0,75 |

| Daily production: | 1000- 1400 pairs |