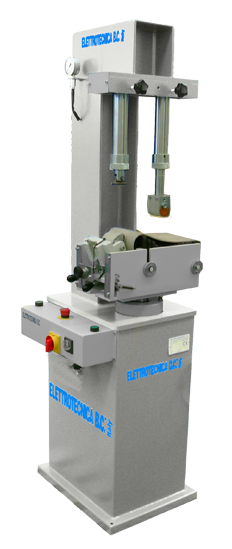

Hydraulic presses for BANF soles application

One of the features that most let us stand out on the market is our long-standing experience: working in this sector for sixty years, in fact, we at Elettrotecnica B.C. have learned to understand the special features and difficulties of footwear production, managing to develop effective solutions to support manufacturers.

Together with us, some historical machines were conceived, such as the BANF hydraulic press for soles application: designed in 1962, it is still known and requested all over the world for its high reliability. This technology has other features that make it so appreciated by manufacturers, such as the distance between the toe-holder support and the pillow that allows working on both normal footwear and boot models without having to make changes. There are also adjustable parameters which optimize the work flow, including the pressing time.

You can find all about our hydraulic presses technical details in our catalog!

Contact us!

Go to the form to ask about our products!

Hydraulic press for outsole application

The distance between the points-holder support and the pillow permits to work on normal shoe and boots without modifications. The adjustement of the pressing varies from 0 to 50 seconds and permits to use any glue. On demand , the machine can be supplied with pillows full of water.

| Technical details | |

|---|---|

| Dimensions: | cm 80 (31”) x 62 (24”) x 182 (71”) |

| Net weight: | Kg 420 (926 LBS) |

| Electric power: | Kw 1.5 |

| Working pressure: | 25 - 50 BAR |