video gallery

Elettrotecnica BC

-

Mod. 5000VACUUM

-

SHOWING ELETTROTECNICA B.C.

-

Mod.CBFS - ROUGHING MACHINE WITH DOUBLE TOOL

-

SEAT AND SIDE LASTING MACHINE - 999 RC

-

SAFETY TOE LASTING MACHINE

-

B.C. ROBOT SAFETY LINE

-

FASHION SNEAKERS LINE PRODUCTION

-

TOE AND SEAT LASTING MACHINE - WOMAN LINE

-

10.000 SQUARE METERS OF FACTORY

-

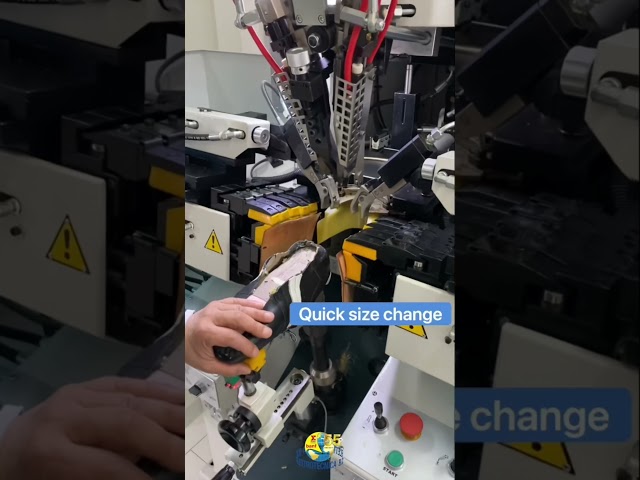

LASTING MACHINE - SNEAKERS

-

PEENING, CHANNEL TAPPING, FLEXIBLE SHOE PROGRAMMING MACHINE

-

SEAT AND SIDE LASTING MACHINE - MOD. 980DT